Homemade Valentine’s Day treats get a boost of flavor from cocoa powder, either natural or Dutch-process. But what’s the difference?

Americans love chocolate, but we don’t generally know much about it, including how to handle it in the kitchen. Cocoa powder, for example, gets a bad rap for being an inferior product to, say, baker’s chocolate. On the contrary, cocoa powder is the pure essence of chocolate, without any added fat or sugar to detract from its inherent goodness. In fact, if we were forced to choose, we’d rather have high-quality cocoa powder in the test kitchen pantry than chocolate itself.

If you’re a Good Eats fan or a frequent user of our recipes, you may have noticed the delineation “natural cocoa powder (not Dutch-process)” on a few of our chocolate applications. Why? Well, the answer is both simple and complicated. Essentially, not all cocoa powders are created equal.

The History

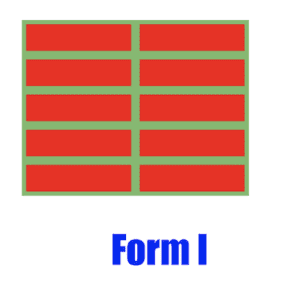

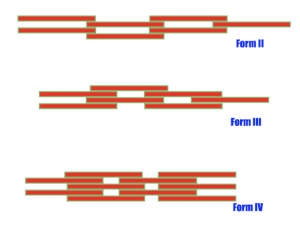

In 1828, a Dutch chocolatier named Casparus van Houten, Sr. patented a screw press capable of squeezing chocolate liquor — not a type of alcohol, but rather cacao nibs crushed to a paste — so that the fat or cocoa butter could be separated from the cocoa solids or “cake.”

Finely crushing the densely packed cake gave birth to natural cocoa powder, which is easily recognized by its brick-red color and bitter flavor.

His son, Coenraad Johnannes van Houten is sometimes credited with the invention. Either way, the younger van Houten continued tinkering and found that by treating the cocoa with an alkaline solution, the flavor of the powder mellowed, and the color darkened quite a bit. To this day, this type of cocoa powder is referred to as Dutch-process or “Dutched” cocoa.

Since they don’t taste or look anything alike, the well-stocked pantry should be home to both natural and Dutch-process powders. They are not always interchangeable, especially in baked goods where the difference in acidity can really throw things off.

The Process

So, where exactly does cocoa powder come from? It’s actually a natural extension of the chocolate-making process:

- Cacao pods are harvested, halved, and emptied of their pulp-covered seeds.

- The seeds and sugary pulp are piled into heaps, covered, and left to ferment in the tropical sun… Yes, chocolate is fermented.

- Once the seeds turn dark brown, they are thoroughly dried, cleaned, packed into sacks, and shipped to chocolate manufacturers all over the world.

- The beans are roasted, similarly to coffee.

- The roasted beans are placed in a winnowing machine, which cracks open the shells. Fans blow away the shell fragments. The remaining interior part of the bean is called the “nib.”

- The nibs are ground into a liquid-y paste called cocoa liquor, which does not contain alcohol, but is roughly equal parts fat (commonly called cocoa butter) and non-fat cocoa solids.

- This liquor goes into large hydraulic presses, which squeeze the cocoa butter out. The remaining solids are broken into a fine powder, aka cocoa powder.

The Recipes

Now that you’ve been acquainted with the magic of cocoa powder, let’s try some decadent applications:

Chocolate Syrup: Reloaded

Black cardamom and Dutch-process cocoa powder add depth of flavor to this rich, homemade chocolate syrup.

Cocoa Brownies: Reloaded

Natural cocoa powder takes center stage in these fudgy brownies. A short rest in the middle of the bake results in a gooey center and flaky crust.

Hot Cocoa: Reloaded

Toasted milk powder introduces notes of caramel, toffee, and malt to this Dutch-process cocoa powder-based homemade hot chocolate mix.

Cocoa Whipped Cream

Our homemade hot cocoa mix shows its versatility as a chocolate flavor agent in this light whipped cream frosting.

Midnight Mug Cake For 2

Made with both Dutch-process cocoa powder and chocolate chips, this double-chocolate mug cake comes together in just 15 minutes for the perfect Valentine’s Day or date-night dessert.